Household Sewage

Are you a homeowner? True Water design, manufacture, and install, household wastewater treatment systems for all project requirements.

- Design & consultancy

- Council approvals

- Home sewage treatment systems

- Land application area options

Commercial Sewage

True Water specialise in delivering superior wastewater and sewage management outcomes for all commercial and industrial applications.

- Design & consultancy

- Regulatory approvals

- 5kL to 500kL treatment systems

- Flexible supply, install, and operate models

Community Sewage

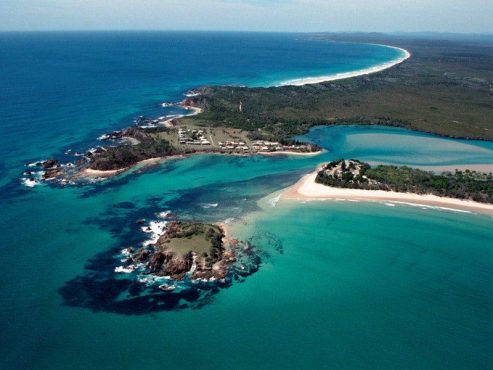

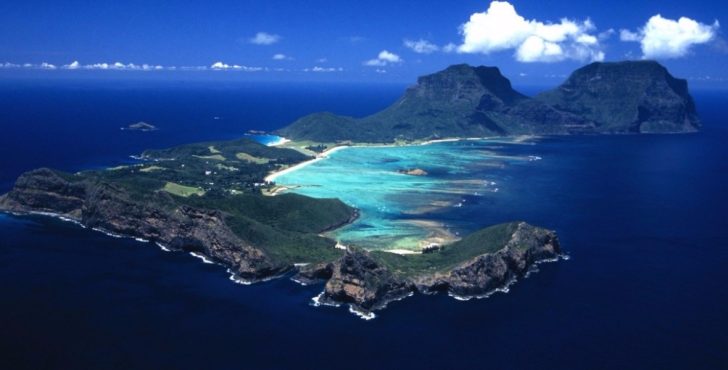

True Water is a licenced wastewater utility delivering services to small-to-medium size communities (50-5,000Ep).

- Unlock development before municipal sewage

- Regulatory approvals

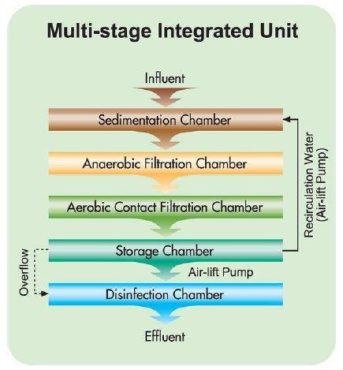

- ISO-certified treatment technologies

- Infrastructure models to suit all site constraints

True Water is the leading industry provider of site-specific wastewater treatment solutions throughout Australia and the Pacific.

Implementing sewage infrastructure delivery requires detailed planning. Our team provide specialist project management services to clients with household, commercial, and community requirements. We take responsibility for every project phase; from consultancy and regulatory approvals, to design, installation, and maintenance.

True Water uses a common sense, collaborative, and communicative approach to engineering end-to-end infrastructure that meets all environmental, financial, and operational objectives. Over the last 15 years, we have secured more than 2,000 government approvals for our technology, which has a combined treatment capacity of five million litres per day.

Vision

To deliver sewage and wastewater treatment infrastructure that best addresses the interests of current and future generations.

Mission

People. Water. Environment. Through comprehensive management of wastewater, True Water aims to protect the natural environment, safeguard public health, and improve quality of life.